- Home

- Corporate

- Products

- Steam Boiler

- Steam Generator

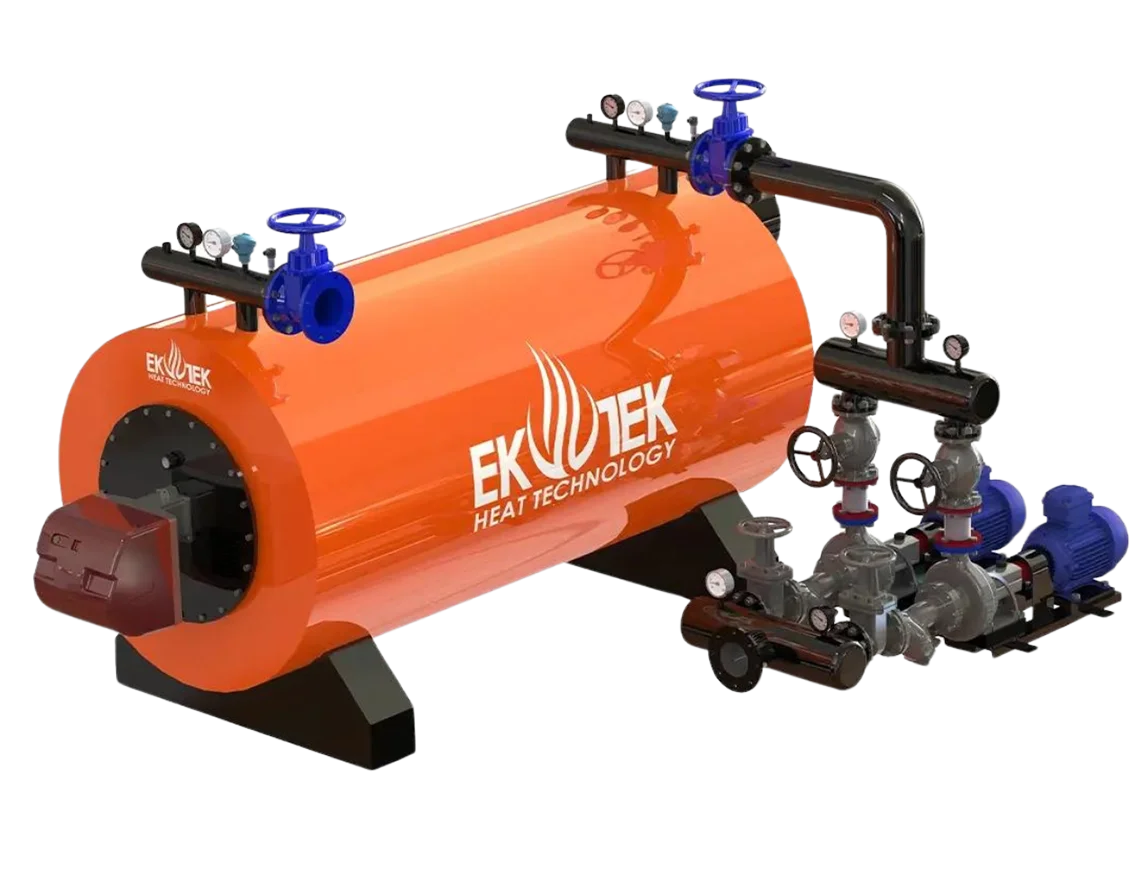

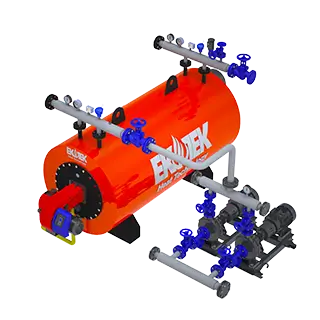

- Thermal Oil Boiler

- Superheated Water Boiler

- Mobile Boiler Rooms

- Hot Air Boiler

- Central Heating Systems

- Residential Boilers

- Hot Water Boiler

- Pellet Boilers

- Custom Made Boilers

- Hot Water Storage Tank

- Tanks

- Condensate Tank

- Degasser Tank

- Shell and Tube Heat Exchangers

- Accumulation Tank

- Economizer

- Accessories

- Media

- References

- After Sales

- Contact Us