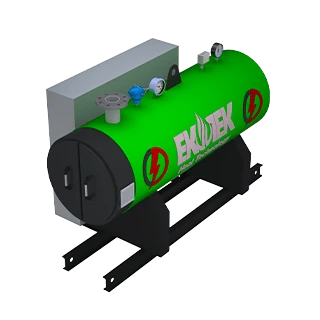

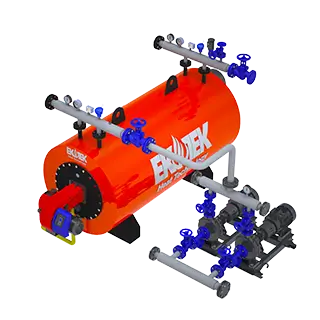

Thermal Oil Boiler Working Principle

Thermal oil boilers, also known as hot oil boilers, are essential equipment in various industrial processes that require consistent and high-temperature heat transfer. Unlike traditional steam boilers, thermal oil boilers use thermal oil as a heat transfer medium, offering several advantages such as higher temperature ranges and lower operating pressures. In this article, we will explain the working principle of thermal oil boilers and their key benefits.

How Does a Thermal Oil Boiler Work?

The working principle of a thermal oil boiler is based on heating thermal oil (also called heat transfer fluid) and circulating it through a closed-loop system to transfer heat to various processes. Here’s a step-by-step explanation:

-

Heating the Thermal Oil:

The thermal oil is heated in the boiler using a burner, which can operate on fuels such as gas, oil, or biomass. The oil is heated to the desired temperature, typically ranging from 150°C to 400°C (302°F to 752°F).

-

Circulation of Hot Oil:

Once heated, the thermal oil is pumped through a closed-loop system using a circulation pump. The hot oil flows through pipes and heat exchangers to transfer heat to the intended process or equipment.

-

Heat Transfer:

The thermal oil releases its heat to the process, such as heating reactors, drying systems, or other industrial equipment. After transferring heat, the oil cools down and returns to the boiler for reheating.

-

Closed-Loop System:

The thermal oil operates in a closed-loop system, meaning it is continuously recycled and reused. This minimizes waste and ensures efficient heat transfer.

-

Temperature Control:

Modern thermal oil boilers are equipped with advanced control systems to maintain precise temperature levels, ensuring optimal performance and safety.

Advantages of Thermal Oil Boilers

-

High-Temperature Capability:

Thermal oil boilers can achieve higher temperatures compared to steam boilers, making them ideal for processes requiring precise and high-temperature heat.

-

Low Operating Pressure:

Unlike steam boilers, thermal oil boilers operate at lower pressures, reducing the risk of explosions and enhancing safety.

-

Energy Efficiency:

The closed-loop system minimizes heat loss, resulting in higher energy efficiency and lower operating costs.

-

Versatility:

Thermal oil boilers can be used in a wide range of industries, including chemical, food, textile, and oil and gas.

-

Durability and Reliability:

High-quality thermal oil boilers, like those offered by Ekotek Heat Technology, are designed for long-term performance with minimal maintenance.

Applications of Thermal Oil Boilers

-

Chemical Industry:

For heating reactors, distillation columns, and other chemical processes.

-

Food Industry:

For frying, baking, and drying processes.

-

Textile Industry:

For dyeing, drying, and finishing fabrics.

-

Oil and Gas Industry:

For heating crude oil and other hydrocarbons.

-

Renewable Energy:

In biomass and solar thermal power plants.

Why Choose Ekotek Heat Technology?

-

25 Years of Experience: We specialize in designing and manufacturing high-quality thermal oil boilers.

-

Custom Solutions: Our boilers are tailored to meet the specific needs of your industry.

-

Energy Efficiency: We prioritize energy-saving designs to reduce operational costs.

-

Safety and Reliability: Our boilers are built to the highest safety standards.

-

Comprehensive Support: From installation to maintenance, we provide end-to-end services.

Thermal oil boilers are a reliable and efficient solution for industries requiring high-temperature heat transfer. Their unique working principle, combined with advantages such as low pressure and high efficiency, makes them a preferred choice for many applications. If you’re looking for a high-performance thermal oil boiler, Ekotek Heat Technology is here to help.

Ekotek Heat Technology – Your Trusted Partner in Thermal Oil Boilers!